Inside Our Factory

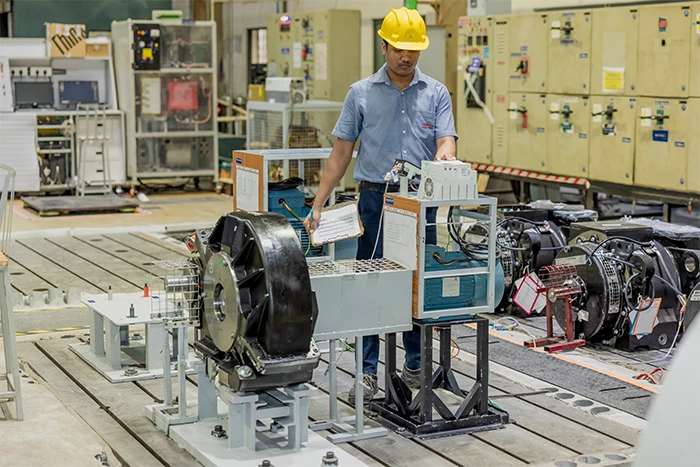

MTEPL’s manufacturing plant is equipped with the latest European technology, ensuring we deliver products that meet international standards. Our facility boasts advanced machinery, automated production lines, and rigorous quality assurance protocols, enabling us to produce high-quality products consistently. We are committed to maintaining a cutting-edge facility that supports our mission of innovation and quality.

Nestled within a spacious 15,175 square meter facility, with 5,836 square meters dedicated to production, MTEPL’s operations are powered by an impressive 1500 KVA installation.

MTEPL has the following in-house production facilities

- Core stacking

- Pressing

- Induction brazing

- TIG/MIG/MAG welding

- Coil making and Winding shop

- VPI

- Dynamic Balancing

- CNC turning machine

- Painting

- CMM

- Type Test and Routine test facilities as per IEC standard

MTEPL has a strong supplier base for various input materials in addition to the in-house stringent quality controls which ensure the world-class quality and reliability of our products.

Newer technologies, production processes, and systems are regularly studied and implemented to ensure continuous improvements in manufactured products.